Giving Tours to Students – CM Tips for a Tailored Tour

Giving Tours to Students – CM Tips for a Tailored Tour

While it may not feel like it, the hard part is largely done. There are just a few best practices we wanted to be sure to cover from the component manufacturers (CMs) who have shared their perspectives over the course of this four-part series. Here are a few things to keep in mind as you prepare to welcome your next group of students.

“Break up the class into smaller groups,” advises Mike Petrina at Wisconsin Building Supply. “Groups of ten or less is best as it’s easier to get and keep their attention as well as get them engaged with questions.” Also, says Mike, it’s okay to insist “no cell phones.”

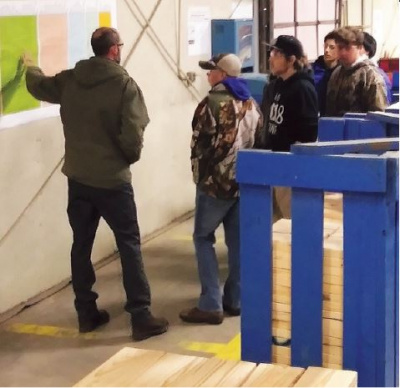

Dallas Austin takes a few minutes to review their skills and authorization matrix with a small group of students to show how Big C approaches employee development and promotion from within the company.

“Make it a conversation,” suggests Will Noonan at Cascade Mfg Co. “Kids enjoy the time outside of the classroom, so be interactive and informal. Encourage questions.” Will also recommends keeping any presentation before or after the tour to a reasonable length so as not to lose their attention.

“Connect with them on a personal level,” says Tony Acampa at Shelter Systems. “Most students are nervous or don’t know what to ask.” Tony says he and his colleagues try to ask about what they are studying or what they want to do when they’re done with school. “If you can create a personal connection,” says Tony, “that leads them to be more comfortable to ask a question.”

“Keep it simple,” reminds Big C Lumber’s Dallas Austin. “You usually only have about an hour with the kids.” He recognizes that it can be hard to draw young people out and get them to ask questions. He suggests having a few things on hand to reward interaction. “The first kid to ask a question gets a Big C lanyard or pop socket for his phone,” he explains. “It gets them to engage more.”

“Feed them lunch,” says Bob Mochinski at Littfin Lumber Co. “You get their attention when you feed them.” With more than 30 years under his belt touring with students and building relationships at his local technical college, Bob knows you can’t go wrong on that front.

Engineered Building Design’s Production Manager Larry Northway gives a tour to seniors in the Advanced Manufacturing and Welding program at Kirkwood Community College in Iowa City.

Script or No Script?

Some CMs start their tours in the office and follow a plan that comes in as a quote through scheduling and design and then out to the plant for production and delivery. Other CMs focus their tours on following a board through the process, from the bunk of lumber on one end of the plant through to the stack of trusses on the other end. Only 24 percent of the CMs who responded to the SBC Industry News poll earlier this year indicated that they utilize a formal script or outline in the process of giving a tour, so it doesn’t have to be the same every time. In fact, regardless of their preparation process, the CMs who have become seasoned at giving tours emphasize the need to tailor them based on the group’s age and interests.

“Get insight from the teachers,” advises Richco Structures’ Justin Richardson. “A construction class will be tailored more to production. A home design class will be more technical.” Focusing the tour on what is most relevant to what the students are learning in the classroom helps teachers with their lesson plans, making it more likely they will want to return in the future.

“Utilize the experts in different departments to share their knowledge as needed,” recommends Joseph Maez at Katerra, Inc. He says his tours are “led by the group’s questions” because in his experience, “tours become more interactive when you let the group drive you where it wants to go; it spurs more questions.” Joseph does warn that this approach only works if you’re comfortable with the possibility of not getting to everything you planned to cover. “I’ve had tours where I don’t finish because of staying where the group is interested,” he says.

“Make it hands-on and fast-paced,” recommends Dean DeHoog at Standard Lumber (see below). Ten years ago, Dean says the plant where he worked would have groups build a truss in the shop under their supervision. “We’d have the pieces all cut and set up and if the group wasn’t too big each person put on their own plate. Then they’d see it get rolled and we’d let them sign it.” After getting them loosened up with “something they can touch and feel and work on,” Dean says they would then do five minutes at hands-on stations in the office: truss building, load transfer, calculations, math games. In Dean’s experience, “going through the shop first loosened them up” making them “more open when they went into the office for the station activities.”

Last but not least, David Mitchell at Engineered Building Design, L.C. suggests making one key point regardless of the group’s size, grade level, or areas of interest. “Stress what a good worker is like,” he says. “Emphasize life skills to students whenever possible: Show up, work hard, find opportunity.”

Hit a Roadblock? Go to the Students

In a past life, Dean DeHoog had the opportunity to bring students into the plant for some hands-on learning, in some cases providing kids the chance to set plates and watch “their truss” go through the finish roller. Today, however, as he’s working to get young people interested in the construction trades in the inner city of Grand Rapids, Michigan, he’s finding that teachers have a hard time getting students out of the schools. “They just don’t do field trips like they used to,” he says.

So Dean and his colleagues have been spending more time giving virtual tours in the classroom using videos of the manufacturing plant and designers at work. “We usually bring a truss designer along to discuss layouts and drawings,” Dean explains. “Showing a truss designer sitting in front of three or four monitors and using a gaming mouse gets the kids’ attention.”