It’s a Blue Light Special

It’s a Blue Light Special

In component manufacturing, forklifts are very useful but can also pose an injury risk to employees working around them. According to OSHA, approximately 35,000 serious injuries and 62,000 non-serious injuries involving forklifts occur in the United States every year. While not all of these injuries are related to forklift travel, bright blue spotlight technology has the potential to reduce the risk of injury for those working around moving forklifts.

Mark Russell, employee engagement manager at Millard Lumber, learned about blue safety lights after a visit from his insurance provider. “I did a walk-through in early 2018 with their safety engineer manager and he suggested we add them to our fleet,” Mark says. “I ordered them right after he left and they got delivered the next week. It was really easy to find them on Amazon.”

Millard Lumber has 25 forklifts operating at three locations. Before the blue lights, their forklift drivers were expected to use their horns when driving into areas where people wouldn’t be able to see them. “We continue to have them use their horns,” Mark says, “the blue lights are just an added safety measure.” While it’s not definite proof they are 100 percent effective, Millard hasn’t had any recent forklift-related safety incidents.

So Why Blue?

Blue light is a short wavelength in the light spectrum, which means it produces higher amounts of energy and is therefore brighter and easier to see. That means it’s also easier to see around corners and in tight spaces.

“They certainly make the forklifts more visible,” Mark says. And they weren’t difficult or time-consuming to install. Each forklift was outfitted with two lights, one for the front and one for the back. “Our maintenance team went through and installed them when they were readily available ‘offline’ as part of the general maintenance process.” The remaining installations occurred on Saturdays when the forklifts were less busy.

A serious forklift injury could add up to thousands, even hundreds of thousands of dollars, in direct and indirect costs to an employer. In contrast, a very small expenditure on blue lights could save a lot of money and potentially serious injury. According to Mark, he invested less than $100 and a bit of labor to equip each forklift with two lights. This is a low cost, high value opportunity.

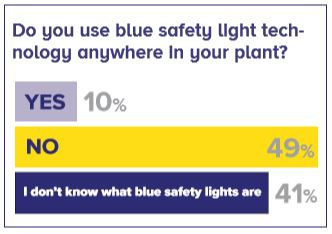

Blue lights have been in use in manufacturing for a few years but they aren’t being widely used in the component manufacturing industry. A recent SBC Industry News poll indicated that nearly 90 percent of respondents either didn’t currently use blue lights or weren’t even aware they existed.

Sure, it’s likely your forklifts are already furnished with back up alarms or strobe lights. Unfortunately, hearing and seeing these daily can become irritating for production employees. Furthermore, those alert systems don’t allow other forklift drivers and pedestrians to quickly identify which direction and how quickly a forklift is traveling. Blue safety spotlights cast a large, bright light on the ground in front of or behind the forklift. This large area makes it easy for employees to notice and is more apt to catch someone’s attention through their peripheral vision.

As the old adage goes, it’s better to be safe than sorry. And for a minimal financial and time investment, you can add a layer of safety to your forklifts next week. Shed some (blue) light on your safety practices and order some blue lights today.

For Your Maintenance Team

One thing to note is that it’s important to ensure the wiring is done correctly when installing aftermarket blue safety lights. If you’re planning to install one light on the front and one on the rear of the forklift, wire the lights so that only the relevant light comes on when the forklift is moving in either direction. Wiring them so that they are always on isn’t nearly as helpful and is more likely to cause confusion than assistance. Forklift spotlights should only be on when a hazard is present, such as when the forklift is in motion toward the direction the light points.