Are You Making Money on Your Waste?

Are You Making Money on Your Waste?

Twenty-five years ago Jay Asgari, the CFO at Truss Tech Industries, Inc. in Buford, Georgia, wanted to find a better way to dispose of their wood waste. He did his research and believes it came down to a few alternatives. “We could make wood pellets and use them for heating or use a boiler, but that didn’t make sense for us in the south,” says Jay. “The other option was to find a company that would buy our wood waste, so I looked into mulch companies in our area and found one that was 30 miles from me. I went and talked to them and they ended up buying our wood waste.”

Jay explains, “Before we found the mulch company, we were running three shifts and I had been paying over $10,000 a month for wood waste disposal at the landfill.ˮ Rather than constantly haul out the wood waste with his own trailers, he decided to purchase a wood grinder and grind it in-house. “There are some mulch companies that require you have a live-bottom trailer, and I didn’t want to buy two of them and have to continually handle the transportation part of it. Instead, I invested $120,000 in a grinder system. This was an economical decision for me to make and it was easy to justify the investment,” says Jay. “Within a year, our grinder system paid for itself. Not to mention, I was also making money selling the ground up wood waste at $350 a trailer.”

Fast-forward to today, and although the mulch company no longer buys their wood waste, they’ve transitioned to a similar process with a particle board company. “The mulch company bought our wood waste for 15 years, but they eventually sold and stopped buying from us,” shares Jay. “I started looking for a substitute. Some places were saying I’d have to pay them, and I said no, I’ll find someone to buy from me. I didn’t want to give it away for free, I wanted to put a dollar sign on it. Now we sell the wood waste to a company that uses it for particle board and they’ve been buying from us for the past ten years.”

“We were making $350 a trailer with the mulch company, but because the particle company we sell to now is about 75 miles away we came down on the price to $250 a trailer to make it worthwhile for them. They’re happy and I’m happy, so we all win.”

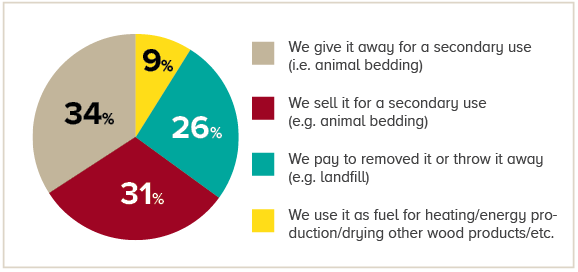

In a recent SBC Industry News poll, we learned that 31 percent of CMs sell their sawdust for a secondary use, and 34 percent give it away for a secondary use.

How did Jay find the particle board company? He made the connection through a neighboring company. “I called a neighbor that owned a cabinet manufacturing company and asked what they did with their wood waste,” explains Jay. “They gave me the particle board company’s number, and because we have a coarse wood waste that’s uniform with no chemical in it they were very willing to use our wood waste and happy to accommodate us.”

The process Jay set up twenty-five years ago is mostly automated and runs completely by a conveyor belt system into a trailer. “We have a conveyor belt that goes from our saws and sends the wood waste through a wall cavity to a conveyor belt outside. That conveyor belt empties the waste into a wood grinder that grinds it up into wood chips. From there it is blown into a covered trailer. When the trailer is full, which is usually three to four days depending on production, we just call the particle company, and they pick it up the next day.”

Jay’s operation is just one example of how component manufacturers (CMs) can dispose of their wood waste and sell or donate it for a secondary use. In future articles, we will look at how other CMs are reusing or disposing of their wood waste. If you have a unique disposal process that you think other CMs would benefit from learning about, please contact SBCA Staff so your story can be shared in future issues of SBC Magazine.