Editor's Message: What Are Your Biggest Pain Points?

Editor's Message: What Are Your Biggest Pain Points?

If there is one New Year’s resolution that is ingrained in almost any business, it is the desire to do better in the coming year than it did the year before. In striving to improve, a good place to start is devising strategies to address your biggest challenges. SBC Magazine recently conducted a survey to find out what component manufacturers (CMs) currently see as their most significant challenges. The answers were all open-ended, and yet the answers surprisingly grouped well into a handful of categories.

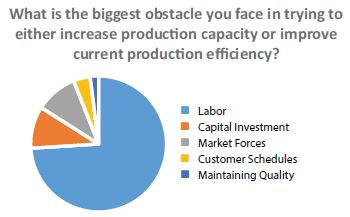

When asked to describe their biggest challenge in improving production capacity or efficiency, 74 percent pointed to labor. While most respondents focused on the difficulty in finding “qualified” employees, some also lamented that it was difficult to find employees who stayed on the job long after hire.

Ten percent of respondents said lack of resources to make large capital expenditures is holding them back, while another ten percent identified external forces like weather that make it difficult to have reliable demand and consistent cash flow. Finally, four percent pointed to struggles with their customer’s lack of consistent scheduling, again affecting cash flow.

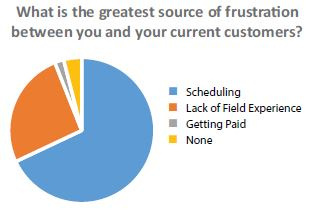

When asked about their greatest source of frustration with their customers, 68 percent gave answers related to a lack of communication and/or consistency with scheduling jobs for delivery. Another 26 percent of the respondents pointed toward issues pertaining to the lack of experience or professionalism in the field. While four percent indicated they didn’t have any frustrations related to their customers, two percent said their biggest challenge concerned collecting payment for their work.

Turning the question of frustration to their suppliers, there wasn’t a dominant answer. Thirty-six percent of respondents pointed toward issues that fell under “logistics,” with answers ranging from not getting raw material deliveries when expected, to not getting equipment repairs quickly enough. Twenty-four percent said they have no frustrations related to their suppliers, while another 24 percent said price volatility, which impacts profitability, were concerns. Finally, 12 percent gave answers that pertained to a lack of quality in the products or services from their current suppliers.

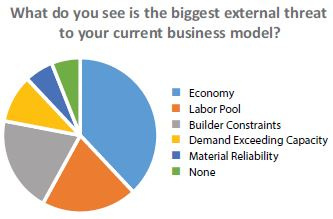

Finally, CMs were asked what they saw as the biggest external threat to their current business model. Poor economic performance was identified by 38 percent of respondents. Twenty percent pointed to systemic employment issues such as low unemployment, regulatory requirements, and a broken immigration system. Another 20 percent gave answers that could be considered “builder constraints” like a lack of lots, financing, or regulatory barriers, which constrain production and cash flow. Ten percent of participants were worried about the impact of demand continuing to exceed capacity and how that might lead builders to seek other options. Finally, six percent pointed to lumber quality, identifying waste and appearance as significant issues.

Hopefully, these answers from CMs across the country provide you with a broader perspective as you identify your top challenges and opportunities for improvement in 2020.

From all of us at SBC, we wish you a happy and prosperous new year! Thank you for your support and for reading and engaging with the content we publish both in print and online.