Impacts of Weather & Truss Storage Conditions

Impacts of Weather & Truss Storage Conditions

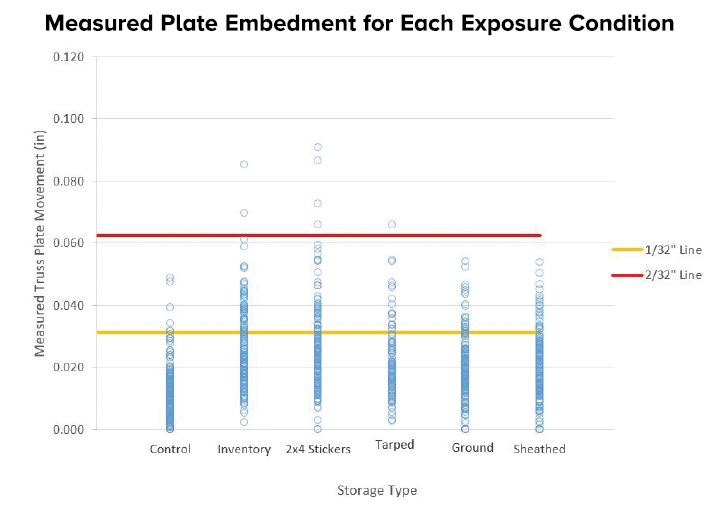

SBCA committees and staff undertook a rigorous testing program to better understand the effects that weather can have on truss performance (see Sept/Oct 2019). This testing took place in three locations over the course of approximately four months. These trusses were then shipped to SBCRI, QC measurements were taken, plates were re-pressed when the plate movement was greater than 1/32", and the trusses were tested for structural capacity. Let’s look at how this testing was done, what measurements were taken, and how that translated into the data displayed in this graph.

A graph can be worth more than a thousand words, but sometimes it does need context. Let’s look at what the data points in this graph are telling us, and why it is valuable for component manufacturers (CMs). Click to enlarge.

Plate movement is the dependent variable in this graph, meaning that the embedment was measured and compared between different independent variables or storage types. Plate movement is an important part of truss manufacturing and performance. The less the tooth penetrates the wood, the less holding capacity that tooth has. Testing proved that plates with unsatisfactory embedment could be repressed even if backed out from weather conditions. Using a digital depth gauge, plate movement was measured on eight plates per truss. This graph shows 800 plate embedment measurements, which is a statistically significant sample size. Each plate is represented by one point on the graph. Note that the solid blue areas are points grouped so closely together that the individual points are not discernable.

Control

Control trusses were left indoors, in a relatively temperature-controlled environment. These trusses were used as benchmarks to be compared with the weathered trusses not only for plate embedment but also structural performance.

Inventory

Inventory trusses represent trusses that are stored in a typical yard. This means off the ground and no contact with vegetation.

2x4 Stickers

Trusses on stickers were also stored off the ground but grass, and therefore moisture, was able to grow around the trusses. This is representative of trusses stored properly on a jobsite where clear space comes at a

premium.

Tarped

Tarped trusses were stored both on stickers and directly in contact with the ground. Since trusses are supposed to be loosely covered if stored for longer than one week, we wanted to see what would happen if we tightly covered trusses to trap heat and moisture within the truss bundle.

Ground

Trusses stored on the ground represent trusses that are rolled off the truck and set wherever space is available on the jobsite. These trusses are in full contact with the ground and vegetation was allowed to grow around trusses.

Sheathed

Trusses were also stored well off the ground and covered with typical floor sheathing material. It is not uncommon for trusses to be installed and the floor sheathed without the building being fully dried in. We wanted to see how trusses left in this assembly would perform.

Each column in the graph represents a different storage condition. These conditions were determined by the SBCA Engineering & Technical Committee prior to the start of the test. The purpose of these test conditions was to replicate common, real-world truss storage scenarios. This allows us to compare how different storage methods affect plate movement (i.e., changes in embedment). The important thing to note is that embedment was not measured prior to exposing trusses to the elements. Instead, we created a set of control trusses at each location to act as the benchmark for plate embedment. This way, we could compare embedment of weathered trusses to the embedment of real-world trusses, not the ideal truss with perfect embedment. We also made sure that all the truss groups, other than the sheathed setup, were stored in bundles, as this is most representative of how trusses are typically stored.

Now that we know what we did to weather the trusses and how we measured them to get truss plate movement data, we can make some observations as to what the graph is telling us. Considering that tooth reductions exist (see TPI 1-2014 Table 3.7-1) for plates with movement greater than 1/32", we drew a yellow line at 1/32" to illustrate when the plates exceeded this threshold. There is yet a greater reduction requirement for plates with movement of greater than 2/32", so we drew a red line on the graph to represent that threshold.

When we look at the points, we first see that the control trusses do not have a perfect zero-inch embedment. This reflects real world conditions and is good to keep in mind, because that also means that the weathered trusses likely did not start with a perfect zero-inch plate embedment. Next, we see that there are very few plates that exceeded the 1/32" embedment threshold, and only seven of the 800 plates measured exceeded 2/32". This means that weather-related plate movement is minimal over a 16-week period. Bob Mochinski, VP of operations at Littfin Truss in Minnesota stated that they “closely monitor plate movement, and have seen very similar plate performance from floor trusses left in the yard.” We can also see that the variation in embedment between different weathering conditions is almost negligible. Again, this means that within 16 weeks, storage type is not a big factor contributing to plate movement.

The story that this chart tells is very valuable to CMs because we now have science-based evidence of how different storage and weather conditions affect truss plated joint performance over a four-month period. We have learned the following from this set of data:

- Based on the variety of storage conditions our test specimens were placed in, trusses generally have up to 12 weeks of exposure to weather before embedment (truss plate movement) on any joint is expected to become an issue.

- Truss plated joints that have plate movement greater than 1/32̎ can be repressed to restore the truss to its expected load carrying capacity. Information on this testing will be shared in a future article.

We are now working through what happens to joints exposed to the daily heat of sunshine and periodic high moisture conditions. Given that we have pictures showing truss plate movement of truss plates on the outside of a bundle of trusses, this condition is also important to assess. Once this assessment is completed, the results will be used to write a draft storage best-practice document to help the supply chain manage truss performance when varying weather conditions are present during the period of time trusses are being stored.