Keep Your Employees More Stationary

Keep Your Employees More Stationary

Leveraging the technology on your production floor to increase throughput can take a lot of different forms. One way is to add to your existing infrastructure.

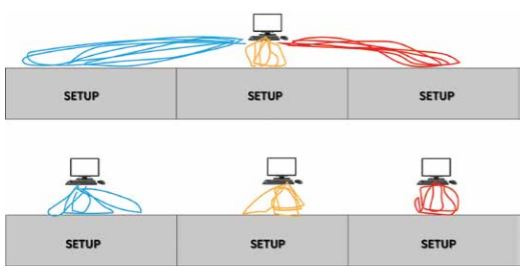

Grab your PPE and head out to one of your manufacturing areas to observe. Do you have multiple employees walking to a single, centralized terminal or computer station that’s really only convenient for one person? Is it adding steps, time, and delay?

Borrowing from lean manufacturing concepts, carefully survey the walking patterns created throughout a shift and determine locations to implement additional terminals to keep foot travel to a minimum.

Borrowing from lean manufacturing concepts, carefully survey the walking patterns created throughout a shift and determine locations to implement additional terminals to keep foot travel to a minimum.

For example, Builders FirstSource recently added two additional computer stations in one area of their new Nashville, Tennessee location. “We basically cut the walking distance one-third or more, which meant we were freeing up two-thirds of the steps a couple of our folks were taking,” explains Chris Cozart, director of component manufacturing systems. “We were able to take that recaptured time and turn it into being more productive in other areas.” The productivity, Chris explains, can be even greater depending on the size of your manufacturing setups.

There are some costs associated with making these kinds of technology upgrades, but the return on investment (ROI) can be incredible once the new system is in place. “Sure, it might take a thousand-dollar buy-in,” Chris adds, “but if the efficiency it creates allows you to push another job through in a day, and the profit from that job is a thousand dollars, you’ve made that investment back in only one day.”