The Original Offsite Framing Solution

The Original Offsite Framing Solution

You may have noticed the emergence of a new phrase to describe the use of components in certain parts of the country. A method referred to as “offsite framing” is catching on in California, Florida, and other areas of high volume housing production. New techniques always produce mixed emotions of fear, uncertainty, opportunity, excitement, and more. Is this a new opportunity for component manufacturers (CMs) or is it a threat to business and a potential loss of market share?

You may have noticed the emergence of a new phrase to describe the use of components in certain parts of the country. A method referred to as “offsite framing” is catching on in California, Florida, and other areas of high volume housing production. New techniques always produce mixed emotions of fear, uncertainty, opportunity, excitement, and more. Is this a new opportunity for component manufacturers (CMs) or is it a threat to business and a potential loss of market share?

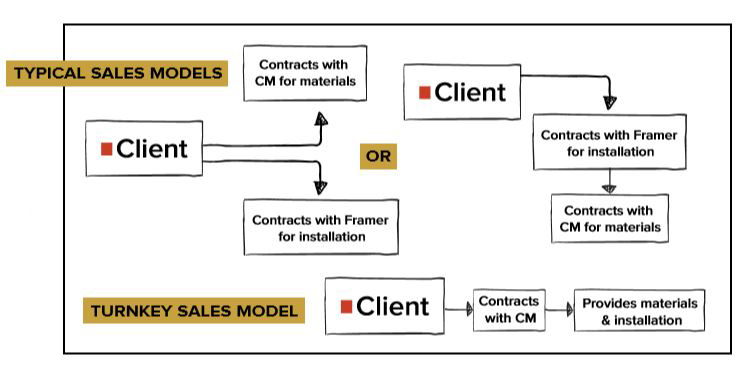

Offsite framing utilizes roof trusses, wall panels, and floor panels combined with installation labor to offer a solution that reduces cycle time, onsite waste, and headaches for the builder. If this sounds familiar, it should. Offsite framing is a reinvention of other industry terms like “innovative framing” and “turnkey framing.” While it may be a superior marketing term, offsite framing is essentially turnkey framing with efforts to highlight the benefits CMs have been advocating for years.

CMs already have access to a number of tools required to provide an offsite framing solution. If you’re like a vast majority of CMs across the country, you manufacture roof and floor trusses, so those capabilities are already in place. If you don’t currently manufacture wall panels, you may have produced them in the past or likely have considered it at some point, so you have a pathway to wall panel production. Floor panels are a relatively simple integration, with most producers laying out joists in an open space and applying sheathing and hoisting connection points in their manufacturing facility. Most CMs have relationships with I-joist and wide dimension lumber alternatives to floor trusses. The most powerful tool CMs have access to, providing the greatest competitive advantage to others looking to enter the offsite framing space, is design software that allows for modeling of structures. This access gives CMs the ability to collaborate with framers with 3D viewers and view potential pitfalls and problems before they occur in the field.

The primary benefit of offsite framing is it puts the CM and framer on the same side of the equation, advocating to maximize efficiency and minimize waste, providing a solution to the builder. Alternatively, when the builder makes component purchases and framing labor decisions independent of each other, conflict is more likely to arise with a “zero-sum” relationship where one side’s profit is derived from the other side’s loss. Combining the manufactured component with the installation labor provides a streamlined solution to the builder and incentivizes the installer to work through problems rather than raise obstructions.

So, how can CMs take advantage of the momentum that offsite framing is gaining across the country? The first step is to search out framers you can work with closely to make builders’ lives easier. Through this relationship, collaborate on ways to create convenience and efficiency for the installer so they can increase throughput by reducing cycle times. If you’re looking to make a more substantial commitment and investment, you may look to form a joint venture with a framer in your market or even to bring framing teams under your umbrella offering a higher degree of control.

Once you have a team in place that is committed to this approach, look to incrementally alter your manufactured product offering to speed installation. This may include manufacturing floor panels that can be set into place. It may be supplying precut framing packages that framers are committed to building in the field. Or it may be venturing into wall panels if you currently only produce trusses. Similarly, producing subcomponents or pre-framed openings is a great way to move your offering in the right direction and improve efficiency in the field.

As builders look to keep pace with housing demand, look for techniques like offsite framing to become more mainstream in efforts to gain efficiency and reduce cycle times. CMs are well positioned to take advantage of these techniques through small changes in their manufacturing offerings, framer partnerships, and intuitive marketing by tweaking their messaging to remain relevant with their contemporaries.