President's Message: Protecting the Value of Your Business

President's Message: Protecting the Value of Your Business

With respect to your business, what do you dwell on before you go to sleep? What’s the first thing you think about when you wake up in the morning? If I were to hazard a guess, I would say the most common answer in our industry right now is related to labor challenges and greater production. Given all we have been learning at the SBCA meetings over the past year, I would argue we also need to be constantly focused on our exposure to risk.

We operate in a very litigious environment. In the construction industry, lawsuits occur all too regularly about everything from breach of contract to construction defects to building performance issues. Unfortunately, it isn’t uncommon for component manufacturers (CMs) to get pulled into lawsuits even if the litigated issue isn’t directly related to the design or manufacture of our products. Any involvement in a litigation is expensive. There is the opportunity cost of spending time on the litigation rather than more important business operations. There is also the potential additional costs of settlement or possibly going through a trial or arbitration.

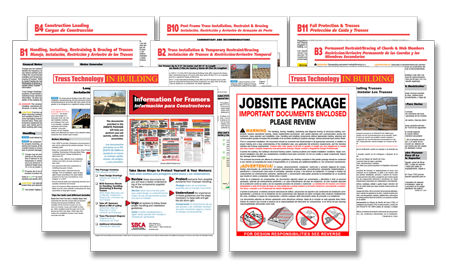

So what can we do to reduce our exposure to the risk? The most common best practice our industry relies on is the Jobsite Package that enables CMs to comprehensively distribute the guidance and warnings contained in the BCSI handbook. This collection of documents is a proven and effective tool for reducing our industry’s exposure to risk with regard to jobsite handling and installation of our products.

A comprehensive and documented quality control (QC) program in the plant is another important activity CMs can engage in to manage their risk exposure. Collecting hard evidence that records everything from proper plate placement and tooth embedment to matching a truss to its truss design drawing is a very important tool for responding confidently to the questions opposing lawyers may ask.

Even further, engaging in a third-party quality assurance program, which is an independent verification that your in-plant QC processes are followed, provides valuable production management data while further documenting the quality characteristics of your products. This data is key to helping identify areas for improvement in your production process, and can help protect you in the event of litigation.

For this reason, SBCA is currently focused on developing a digital method for conducting in-plant QC and third-party QA monitoring. This approach will make inspections easier and yield even more useful management data. If you aren’t currently sending out a Jobsite Package with every job, or you don’t have a comprehensive QC program like SBCA’s In-Plant QC program, you may want to take a closer look into these tools developed to protect the value of your business. Of course, if you have any questions, please contact SBCA staff and they’ll be happy to answer them.