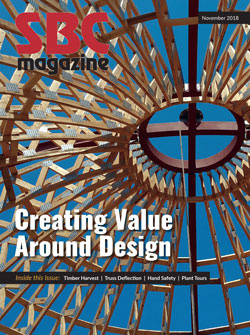

A Straightforward Approach to a Round Design

A Straightforward Approach to a Round Design

Challenging or unusual projects typically stretch a component manufacturer’s (CM’s) operational capabilities in some fashion. The height or span of a truss is limited by the width or length of their gantry table. At times, the weight can present an interesting logistical challenge for material handling equipment and transportation to the jobsite. In the case of the Bosnian Mosque El Salam, located in Granger, Iowa, the trussed dome encountered an unexpected challenge: the design software.

“Our design software has a limit of around 400 individual reference lines, or pieces,” says Ken Knapik, the truss designer on the project for Plum Building Systems (Plum). “Through the process of turning straight boards into a 20-foot-tall curved arch, I tested the limit of the software!”

To appreciate the monumental work accomplished in completing this project, it’s good to get a sense for its overall size and scope and how the design department and production team worked together to get it all done without a hitch.

Bosnian Mosque El Salam

On April 22, the Islamic and Cultural Center Bosniak of Des Moines (ICCB) broke ground on a six million dollar mosque in Granger, Iowa in April. Elvedin Sivac, president of the ICCB, said in a local television interview it is the first mosque built in the state of Iowa.

According to Wikipedia, two common features of a mosque one would see from the exterior is a minaret and a dome.

[The minaret is a] tall, slender tower that usually is situated at one of the corners of the mosque structure. The top of the minaret is always the highest point in mosques that have one, and often the highest point in the immediate area…Before the five required daily prayers, a Mu’adhdhin calls the worshippers to prayer from the minaret…A mosque dome, often placed directly above the main prayer hall, may signify the vaults of the heaven and sky.

It’s important to point out that the ICCB is a non-profit organization. Raising the necessary funds to build the intended structure had to come from the community itself. That said, the original blueprints were scrutinized heavily to find opportunities for cost savings.

Helping a Customer

The mosque’s dome was originally designed entirely out of steel. Armin Avdic, owner of Arko’s Custom Homes, served on the ICCB’s board and was curious whether it could be built out of wood instead. He’s been a local single-family custom home builder who has used wood floor and roof trusses for years and understands the benefits of component framing. “In changing the dome from steel to wood, I was thinking of more than just the price,” says Armin. “I was also thinking about worker safety. With wood, we could build it on the ground and crane it up.”

Armin is also a loyal customer of Plum. “We build almost all of his roof and floor trusses, so he came to us first wondering if we could do it,” says Ray Wright, a sales rep for Plum. Armin considers Plum as a valuable partner. “I’m very passionate about the work I do,” says Armin. “When I can work with passionate people like Ray and Jim at Plum, they make me more successful. They are willing to work alongside me, and that’s a big deal.”

The feeling is mutual for Ray, “it feels like we are part of the team. As a result, he is loyal and it’s really hard to find loyal customers in today’s market. That’s why, when I saw the dome project, my immediate reaction was I wanted to be an advocate for us to get it done.”

Fortunately, as Jim points out, “we aren’t ones to shy away from unique projects. Although we had never done anything like this before, we were determined to figure it out.”

Armin was impressed, “when they came back with the bid and showed they could do it, I was so excited!”

A Meaningful Project

“Working on projects likes these are a win for everyone,” says Ray. “We can be a hero for the customer and our great team has an opportunity to show off the great work they can do.” While the mosque is not fully funded or completed, the savings they were able to realize through the roof trussed-dome they can apply to other parts of the structure. Jim adds, “this building was literally outside the box. It was cool to see how we could turn flat boards into a smooth, round dome.”

“What I love most about projects like this is how they push the envelope of what we think trusses are capable of accomplishing,” says Ken. “It also pushes my own limits as a designer.” Not to mention the limits of his software. As this project demonstrates, the real value Plum brought to the project was not the result of having better materials, better production equipment, better software, or even the lowest product cost. It was the passion they had for their customer and their ability to think creatively to design a successful structure.

Triangulating a Dome

To complete the Bosnian Mosque El Salam dome project, the first step for Ray, Ken and Jim was to bring the design and production departments together to discuss the whole process and come up with a reasonable bid. “Since we had such a good relationship with the builder, we knew it was worth the time and effort to get a good handle on the amount of man hours it would take to design and build the truss arches,” says Ray. “It was an unusual application; we couldn’t just throw a square-footage number at it.”

To estimate the time it would take to manufacture the trusses, Jim, Rick Parrino, Plum’s general manager, and Steve Baker, Plum’s operations manager, used a matrix they developed based on shop hour times studies they have conducted over the years. “Given the uniqueness of the design, we had to extrapolate off of some of the more complex designs we’ve built in the past,” says Rick. Ultimately, Plumʼs bid was warmly accepted by the ICCB board.

The dome itself is 20 feet tall and 40 feet in diameter. The dome frame was still constructed out of steel beams, with a tension ring at the base and a compression ring at the top. The trusses were affixed to the steel rings. “The loading conditions didn’t present a challenge, but I spent a majority of the time trying to optimize the chord sections,” says Ken. “I had two goals. One was, to the greatest extent possible, make as many of the chord and web pieces the same.” In talking with production, he knew they would have to juggle a lot of individual pieces, which created a lot of opportunity for error. Ken added, “it wouldn’t be hard to put a similar looking piece in the wrong spot and not notice until they were trying to affix the sheathing and something didn’t line up.”

“My second goal was to minimize the number of pieces to stay within the limits of the software,” says Ken. In his final design, the dome was built using 32, 20-foot-tall arch trusses. Each truss had 16 top chord and 16 bottom chord sections, along with 33-34 webs, for a total of 65-66 pieces each! That one-web range is thanks to what Jim described as the one curve ball they were thrown during the design process. “There was a pitch to the tension ring in order to match the slope of the roof it sat on for bulk water management,” says Jim. Over the 40-foot diameter of the dome, that pitch resulted in a little over a one-foot drop from back to front.

Since the dome couldn’t pitch forward, the arches needed to be altered slightly to accommodate the change in the base ring elevation. With the pitch being parallel on the horizontal axis Ken says, “it really was simple geometry to figure out how to stair-step the trusses from front to back. So, instead of having 32 identical arch trusses, I ended up designing 16 pairs of trusses.”

The truss pairs were then installed in a mirrored pattern (see digital edition for images). “So the pair of ‘R1’ trusses were attached on either side of the front-facing steel arch and that pattern was repeated through the pair of ‘R1S’ trusses that flanked the steel arch at the rear of the dome.”

That innovative approach had a big impact on the ease of design and production. “Over 90 percent of each truss stayed the same and I was able to keep all the design changes at the bottom leg of each truss.” (See digital edition for images.)

The smooth design process also made a big impact on Armin Avdic, the builder. “Every project, no matter how big or small, has changes as you go from initial concept to the actual building,” says Armin. “In working with the architect, they looked for ways to charge you for every little change, no matter how small. But with Plum, they always sat down and were willing to work through any challenge to make sure we were all successful.”

Vault of the Heavens

Once the truss arch designs for the Bosnian Mosque El Salam dome project were completed, production commenced. “The production process went really well given the early collaboration work we had done as a whole team on the front end,” says Jim. To help the production crew successfully handle the hundreds of nearly identical pieces, they relied on a relatively new equipment feature. “Our saw was able to print on each piece and label every joint clearly for the guys assembling the trusses,” says Mike Boswell, production manager for Plum. The labels on the ends of each piece made laying out the pieces very straightforward. Further, since each pair of trusses changed so little, the same jig could be used for every setup with only minor tweaks to accommodate the changing base sections. Jim adds, “all that attention to detail means the manufacturing process went very smoothly.” The trussed dome was assembled on the ground at the jobsite. Each wood truss arch was attached to the metal tension and compression rings using standard hangers. Ken says, “The hangers were specified by the architect ahead of time, so all I had to do was design the trusses to accommodate the connections.”

Turning Spaghetti into a Bowl

In the end, the most difficult part of the whole project was the dome assembly itself. Bracing the trusses during installation proved a significant challenge. “The framers originally planned to use the sheathing as their bracing as they went, but they quickly found out that wouldn’t work,” says Jim.

Rick went to the jobsite early on, “the truss arches were both tall and had a slim profile, so they looked a little like spaghetti when they were initially setting them.” The dome design called for three layers of ¼-inch plywood with fasteners that would suck the plywood to the wood trusses and bend the plywood to the curve of the dome. But trying to affix the plywood to the trusses proved impossible without first installing bracing between each truss.

“Bracing is not straightforward with a dome,” says Ken. “Because of the curve, the distance between each truss varies at each joint, so the framer couldn’t just use their standard approach to pre-cut bracing material.” To help, Ken put joint spacing on the truss layout as well as bracing locations (see digital edition for images) so installers could cut their bracing to the right lengths.

Once installed, the bracing was beneficial beyond providing stability to the truss system. It also acted as an additional surface where the 4x8 sheets of plywood could be fastened along the seams.

Fitting into Place

Once assembly was complete, a crane hoisted the dome into place on the roof of the mosque. One of the steel workers on the jobsite was watching them attach the rigging to the dome prior to the lift. He turned to one of the other bystanders and said, “that thing is going to fold up the moment they lift it off the ground.” Rick was standing nearby, he replied, “you’ll be surprised how strong that wood is, they won’t have a problem at all.”

The effort and passion Plum put into this project was not lost on their loyal builder customer, Armin Avdik, “I was so happy we were able to work with Plum. Every time I walk into this mosque, I can look up into the dome, see the vaults of the heavens and remember the work we were able to accomplish together.”