At Great Lengths: A-1 Roof Truss Designs 90-Foot Trusses for Riding Arena

At Great Lengths: A-1 Roof Truss Designs 90-Foot Trusses for Riding Arena

Well, a truss can be designed to span as long as a project requires. Just take a look at the Four Winds Arena, a 20,000 sq. ft. practice riding arena with 90 ft. span trusses designed by A-1 Roof Trusses of Fort Pierce, FL.

While the sheer size of a 20,000 sq. ft. agricultural facility may conjure images of a large box, don’t be fooled. The plans incorporated a number of design elements to give the arena a distinctive look. The structure included hand-framed exterior bearing timber beams, box beam trusses with a full bottom chord to give the appearance of timber, and a second tier of the roof designed with fixed glass windows.

“It’s a design comparable to an old train depot, except this is 40 times the size,” explained Tony Conant, Sales Representative at A-1 Roof Trusses.

Not Their First Dog & Pony Show

The Four Winds Arena is located in the Wellington Equestrian Center in Wellington, FL, an area A-1 is well acquainted with from previous jobs. Having already worked on a number of arena projects in the Wellington Equestrian Center, A-1 was familiar with a project of this scale. “We are one of the primary barn builders, and we come highly recommended for those projects,” said Conant.

Along with being highly recommended, A-1 also had a good, established relationship with the architect, who asked if A-1 wanted to get involved during the project’s design phase. “It kind of gets you in the door in the early stage,” said Conant. That early participation in the project gave A-1 the opportunity to advocate for design options where structural building components best fit the structure’s overall design. “We let the engineer and architect know what would and wouldn’t work.”

Box Beam Trusses for Design & Rigidity

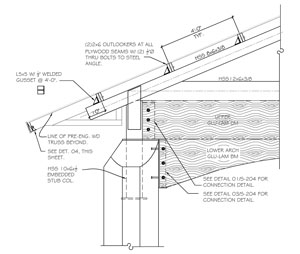

While A-1 is accustomed to projects this size, the Four Winds Arena included some design features outside of the norm. “This project has a unique span with long overhangs,” said Conant. The project also included a large fabricated tube steel gable end truss (see photo above) and hand-framed exterior bearing timber beams (see illustration at right, click to view larger image).

While A-1 is accustomed to projects this size, the Four Winds Arena included some design features outside of the norm. “This project has a unique span with long overhangs,” said Conant. The project also included a large fabricated tube steel gable end truss (see photo above) and hand-framed exterior bearing timber beams (see illustration at right, click to view larger image).

The architect chose to use box beam trusses (see photo below), which the team at A-1 confirmed would work for the design. “Each truss is essentially a two-ply truss with 2x6 segments nailed in between the truss,” explained Conant, noting that the bottom chord had a solid 2x6 between the full length of the truss. Once assembled as a box beam, each truss was 8.5 in. wide and spaced 48 in. o.c. The trusses were side wall piggybacked, to allow for the windows located within the lower portion of the cap truss. The base trusses were set and sheathed prior to hoisting and installing the piggyback trusses.

The design phase ran smoothly for A-1, in large part due to the company's early involvement with the architect and engineer. “Because we were involved in the preliminary stages, the design was pretty simple,” said Conant.

All of the planning and collaboration between the trades paid off at the jobsite. “Box trusses took away a lot of the headaches,” Conant added.

John Herring, CEO at A-1, echoed that sentiment saying, “Erection is critical. Making the box beam out of them, there’s a little more labor, but it makes the trusses stronger and more professional putting them up.”

For all long span projects, A-1 provides a video entitled Handling, Installing and Bracing of Metal Plate Connected Wood Trusses and supplies the BCSI B1-B4 Summary Sheets. Before A-1 will go to production for a job, the customer and the crew flying the trusses must watch the video and sign a letter acknowledging they have reviewed the materials.

The extra rigidity offered by the box beams aided the crane installation on the jobsite. “Flying the box beams, they didn’t need to use as large of a spreader beam, compared to lifting single-ply trusses,” said Conant.

During the installation process, Herring literally had a bird’s eye view of the project’s progress because he could spot the jobsite during his daily commute by helicopter to A-1’s offices. “It [was] really neat the way [they were] putting them up,” said Herring. “I wanted to keep going by.”

Special Delivery

For all of the project’s unique requirements, shipping proved to be the most formidable challenge. “The biggest thing we learned was shipping,” said Conant. While A-1 had some of the longest trailers used in the structural building components industry, transporting the trusses for this job was still a feat. At the plant, A-1 stacked 2x10s underneath the trusses in two locations. Along with the proper escort vehicles, A-1 made its way, slowly but surely, to the jobsite. “We didn’t have issues going down the road or making corners,” said Conant.

For all of the project’s unique requirements, shipping proved to be the most formidable challenge. “The biggest thing we learned was shipping,” said Conant. While A-1 had some of the longest trailers used in the structural building components industry, transporting the trusses for this job was still a feat. At the plant, A-1 stacked 2x10s underneath the trusses in two locations. Along with the proper escort vehicles, A-1 made its way, slowly but surely, to the jobsite. “We didn’t have issues going down the road or making corners,” said Conant.

At the site, A-1 exercised extreme caution delivering the trusses because the owner didn’t want to tear out any of the perimeter of the property. While this mode of transport worked, Conant said they learned some lessons on how to simplify the process. “In the future, we would buy a steel I-beam and chain it to the stack,” he said.

Another Project for the Record Books

For Herring, the success of the Four Winds Arena just goes to show A-1’s specialty in this market. “I think because we’re one of the bigger fabricators in the area, when people want the big trusses, they come to us because we have all the trucks, and we can handle them. It’s not a big deal for us,” he said.